Hey, I thought that West Coast Brewer was a home beer brewing site, why are you making cider?

Yes, it is a homebrewing blog; but I figure that cider making is in the same wheelhouse and that I would share what I learned on the topic in case anyone else was interested in making a batch. The idea of making a batch of cider came to me when I was considering what I wanted to fill my next batch of kegs with. My goal was to having something for everybody. That got me thinking. We all know one of those people who is “Not a beer person”. Whenever I hear someone mutter those words I immediately think that they just have not found the right beer or had a bad beer experience where instead of someone easing them in to beer, they pushed a double IPA on them or gave them a poorly made sour. Although Hard Cider is not beer, many people consider them to be somewhat synonymous with one another and it has to be one of the most approachable alcohols on the planet. It has a low ABV, it is relatively sweet, can be bubbly and has next to no bitterness; it is the gateway drug to beer!

Making cider is easy! Making good cider is a bit more difficult but not too hard if you have the right equipment and a little bit of patience. The good news is that if you are a home beer brewer, you probably have just about everything that you will need in order to make a batch of cider. If not, do not worry, I will go over all of that with you. So you have a few options. If you are happy with mediocrity, I highly recommend you purchase a cider making kit! For approximately $45, you can purchase a Mangrove Jack apple cider kit and create a 5 gallon batch of hard cider that will produce somewhere between a bad and mediocre cider. These kits come with all of the ingredients that you will need, include instructions and make the process very simple. It may not be the best cider you have ever tasted, but it you have never made cider before and have no home brewing experience, this may be a great way to go. You can purchase a Mangrove Jack Apple Cider kit here. You can also find some helpful information on making cider from a kit at HomebrewingDeal.com.

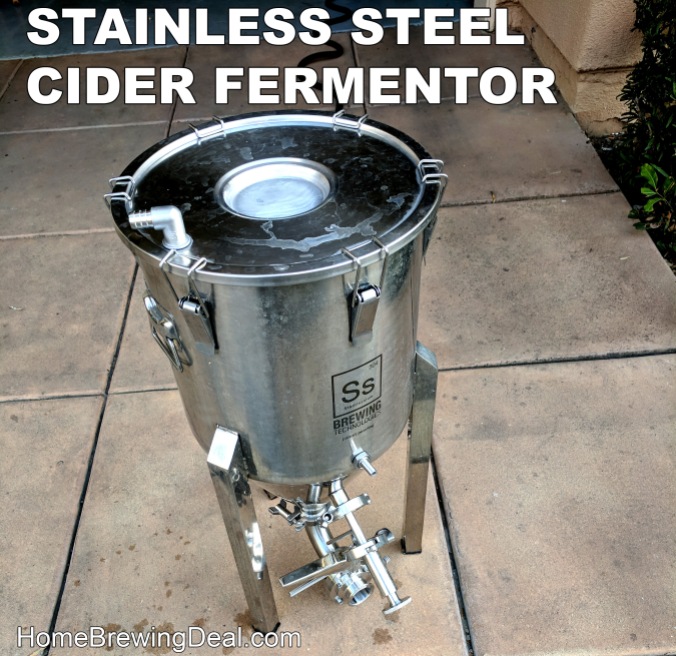

If you have higher aspirations and want to try and create a good to great cider then keep reading and I will do my best to help you reach that goal. The batch of cider that I ended up making was a hard apple cider aged on oak and Oregon Sour Cherries. To make a good cider it is critical to start with the best ingredients possible. Your base ingredient will be apple cider. If you have it available to you from a local apple orchard, pick up fresh pressed cider! If like most people you do not, a great alternative is Musselman’s 100% Apple Cider. It can be purchased at Walmart for approximately $4.50 a gallon. It is pasturized, so there are no additives that will negatively impact your cider and is a great compromise between cost and quality. You need minimal equipment to make cider and the most important item is a fermenter that can hold approximately 7 gallons. If you can swing the price, I highly recommend a Stainless Steel fermenter that will last you a life time. You can purchase a 7 Gallon Stainless Steel Brew Bucket Fermenter here for $199 with free shipping. You will also need to bottle or ideally keg your cider when fermentation has completed. Items for kegging and bottling cider can be found here at MoreBeer for a reasonable price and ship free on orders of $59+. If you need any specific suggestions or help with this, please leave a comment or shoot me an email and I would be happy yo help you. Okay, so here is the recipe that I used to make my cider:

How to guide to making hard cider

Step 1: Prepare for fermentation

Clean and sanitize your fermenter and anything that will come in contact with you cider. If you need a food grade sanitizer, I highly recommend Star San Sanitizer.

Add 5 Gallons of Musselman’s 100% Apple Cider to your fermenter

Add 1 (12oz) container of 100% frozen apple juice concentrate (make sure that there are no preservatives aside from Ascorbic Acid(Vitamin C))

Add 2 Tablespoons of Pectic Enzyme (for clarity)

Add 1 Tablespoon of Yeast Nutrient (for yeast health and a strong fermentation)

Make sure that your cider is at an ideal fermentation temperature for your yeast strain (typically 68 F)

Add your yeast, I like Wyeast 4766 or Cote Des Blancs dry wine yeast; both are great choices for cider yeast.

If possible, take a specific gravity reading. Make sure that your gravity is above 1.045 or else you may have stability issues with your finished cider. You can add additional apple juice concentrate if needed to boost your gravity.

Next seal your fermenter, place it in a temperature controlled location and let it fermenter for 2-3 weeks until your fermentation has completed.

Step 2: Post Fermentation

Once your fermentation has completed there are just a few more tweaks.

Add 1 Teaspoon of Malic Acid (gives the cider a little zip) You may want to add a little more or less depending on your taste

Step 3: Back Sweeten Your Cider or Add Fruit (Optional)

At this point your cider will probably be somewhat dry. I suggest that you back sweeten it to help highly some of the apple flavor it in. In order to do so, you will need to render the yeast unable to ferment the new sugars that you will be adding to the cider. To do so conduct the following steps:

Crush 5 campden tablets and mix it with 1 teaspoon of potassium sorbate and it to your cider. If possible, drop your fermentation temperature down to 45F. Wait 24-48 hours. At this point your fermentation should be completely halted.

A 1 (12oz) container of 100% frozen apple juice concentrate (make sure that there are no preservatives aside from Ascorbic Acid(Vitamin C)) for sweetness and flavor

Add fruit if desired. I added 2 can of Oregon Sour Cherries

Let the cider age at 45 F for an additional 7 Days

Step 4: Transfer Your Cider To The Keg

I use a keg partially because I am lazy and partially because it is the best choice. If you want your cider to be carbonated and you chose to back sweeten or add fruit to it, kegging is your only reasonable choice. Otherwise you will need to add yeast to it once again to force carbonate it in the bottle and risk both over carbonating and undoing all of the effort you placed in to back sweetening the cider in the first place. If you keg, you are able to bottle once the carbonation level that you desire is reached and the cider will come out much cleaner!

Clean and sanitize your keg and anything that will come in contact with the cider.

Transfer your cider from the fermenter to the keg, doing your best to avoid drawing in any of the particulates that have settled to the bottom of your fermenter.

Add oak sticks or oak cubes to the keg for additional complexity if desired. I think it adds a nice touch to the cider. Oak takes time to impact the flavor of your cider, so as it ages in the keg its flavor will become more noticeable.

Let the cider carbonate and condition in the keg for approximately 2 weeks. Your first few pours from the tap will be a little cloudy but after that it should begin to clarify rapidly.

That is it. If all goes well, you should now have a delicious glass of cider in front of you! Please let me know how yours turns out or if you have any comments, questions or suggestion.

Recent Comments